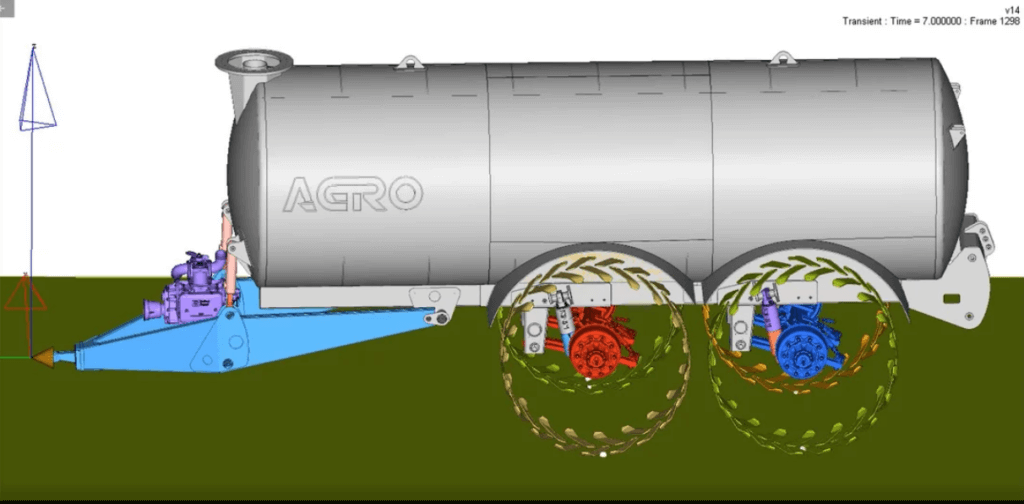

Design modification and prototyping of new slurry tankers. The aim of the modernisation was to reduce the weight of the vehicle thanks to the use of a smaller thickness of metal sheets in the plating construction and lowering the centre of gravity by recessing the wheel arches into the contour of the tank.

Design modification and prototyping of new slurry tankers. The aim of the modernisation was to reduce the weight of the vehicle thanks to the use of a smaller thickness of metal sheets in the plating construction and lowering the centre of gravity by recessing the wheel arches into the contour of the tank.

The first stage of work included numerical calculations of models supplied by the client to ensure the strength and operational safety, including vehicle stability. The second stage of work included field tests of the prototypes using strain gauge measurements. The field tests positively verified the structural and multibody calculations carried out previously.

The prototypes were approved for use and received significant attention at agricultural fairs for being both innovative and safe.

Trends in energy management, the development of electric and hybrid vehicles, as well as innovations in fleet management and labor optimization are influencing manufacturers and operators of off-highway machinery. The application of modern solutions from these areas can significantly contribute to improving the energy efficiency of the entire off-highway sector.

Read moreDue to its practical as well as aesthetic functions, the ‘grill’ is one of the vehicle components that receive special attention in terms of design. What does this process look like from the initial concept stage through to series production?

Read moreIntroducing a flawless product has always been a goal of all OEMs in the Automotive Industry. Unfortunately, product development has become more complex over the years. A growing number of suppliers involved creates a situation requiring checking if teams provide the correct elements of your final product. The purpose of ASPICE is to assess process steps and give tools to put a rating of your partners’ process development.

Read more