Introducing a flawless product has always been a goal of all OEMs in the Automotive Industry. Unfortunately, product development has become more complex over the years. A growing number of suppliers involved creates a situation requiring checking if teams provide the correct elements of your final product. The purpose of ASPICE is to assess process steps and give tools to put a rating of your partners’ process development.

ASPICE (or Automotive SPICE) is a standard framework applied to company processes to avoid risks and minimize failures on the end user. It provides methods to score each supplier and their whole process structure.

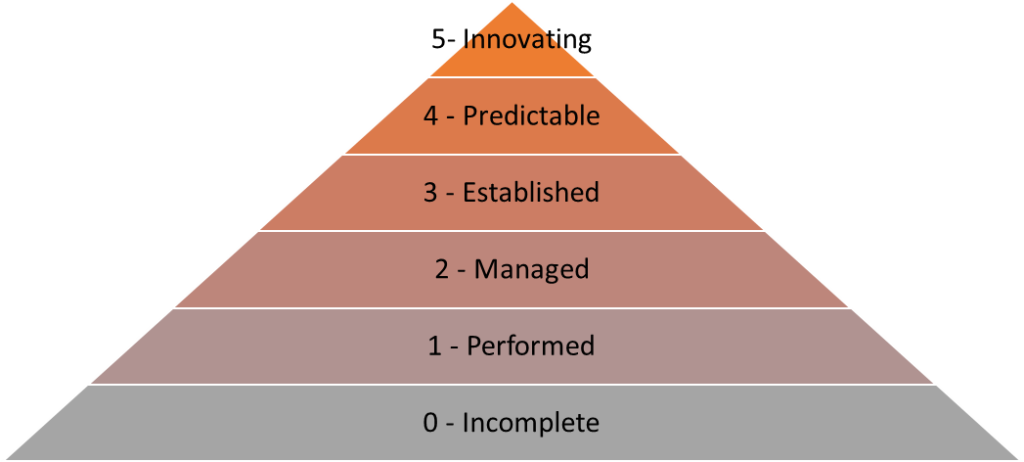

Within the ASPICE framework, you score processes with a 0-5 capability determination scale.

Each level means:

To simplify the approach, most OEMs are looking for partners that can achieve level 2 or 3, which gives OEMs reason to believe that a partner delivers correctly created elements. It lets OEMs avoid problems at the end of product development. Level 2/3 represents a situation where your organization has:

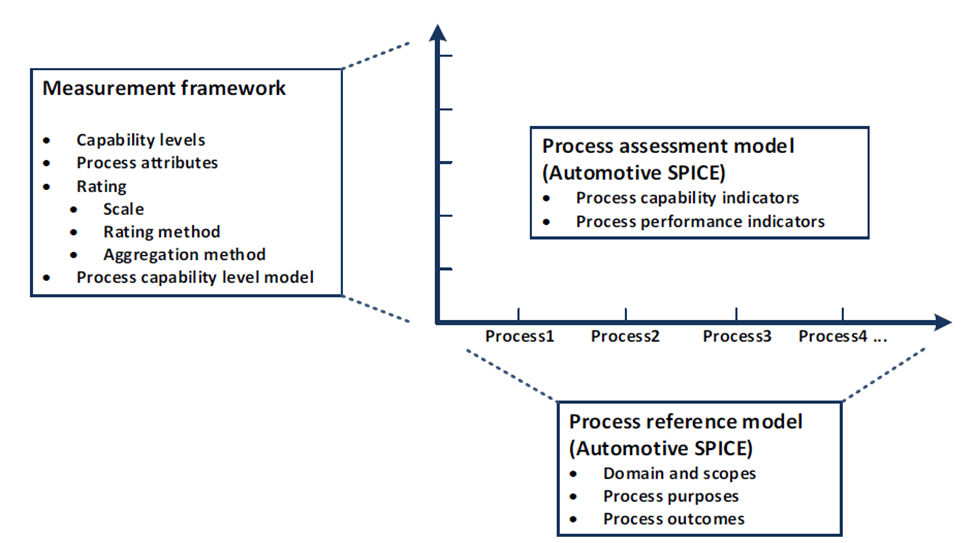

The assessment process bases on a two-dimensional framework (graph from official AUTOSAR Guideline V4.0):

The Y-axis points let us assess each process step individually.

The X-axis follows an assessment of the process step based on points/practices provided by the ASPICE standard.

To better understand the scoring system, we need to introduce some wording in ASPICE:

In addition, each process step in ASPICE is described by:

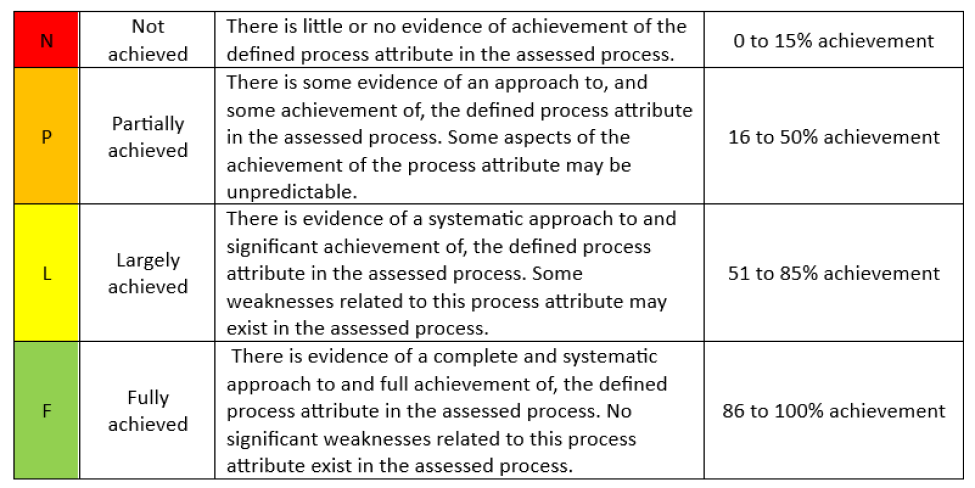

Assessment score is based on scale NPLF where letters stand for:

To achieve capability level 1, a company needs to get a score of L or F on corresponding process attributes. PA1.1 has only one generic practice. It is to fulfill all base practices associated with the assessed process steps. Each step is scored individually.

To achieve capability level 2, you need to achieve a score of F on the previous level (PA1.1) and at least L or F in the newly introduced PA2.X points attached to it. The same logic applies to achieving levels 3, 4, and 5.

Rating your capability level will give you an overview of where your process is, where there are flaws and possible corrections.

If you would like to find out more about ASPICE, I suggest looking for free guideline documents and a pocket guide that can help you understand each process step. Next time, I will try to explain how to use ASPICE to asses your product life cycle processes.

If 2024 was a warm-up lap, 2025 was the moment the automotive industry went full throttle. Electrification matured, SDV programs shifted from prototypes to production intent, and OEMs began to fundamentally rethink how they build, integrate, and scale technology across entire vehicle platforms.

Read moreThe past few years have been challenging for the European automotive sector – production declines, supply chain disruptions, and intensifying competition from Asian manufacturers have forced many companies to downsize. Now, as the market slowly begins to recover, businesses face a new challenge: how to quickly restore their delivery capacity when skilled specialists are in short supply?

Read moreModern automotive lighting is no longer limited to a purely functional role. LED logos, illuminated grilles, and dynamic light animations are becoming a new communication language for car brands. How does the combination of design and technology turn light into a recognizable brand signature?

Read more