There are many indications that the future of public transport lies in environmentally friendly, functional, and comfortable buses capable of efficiently transporting passengers from A to B. How does one go about designing vehicles that meet these criteria?

When designing modern, safe, and efficient buses that meet the challenges of sustainability and passenger diversity, it makes sense to enlist the help of specialists. If you want to access trustworthy, comprehensive technical analyses and strength calculations without having to recruit a multidisciplinary team of experts, it is worth enlisting the support of Endego. The company is distinguished by its advanced approach to bus manufacturing and boasts the full set of competences needed to create a project, from structural, functional, and stylistic foundations to preparing the vehicle for series production. In the following article, Robert Kordus – Team manager, Competence Centre Exterior at Endego, takes a closer look at the process of designing buses according to the company’s approach.

Electric and hydrogen buses dominate Endego’s projects. Although their prices may be higher than those of traditional diesel vehicles, EU subsidies make them increasingly attractive to operators. Although the charging time for electric buses is up to several hours, charging technology at bus stops is becoming more common, which will allow for easier and more practical use.

Hydrogen-powered buses are environmentally friendly. They emit only water during combustion. They are therefore ideal for cities seeking to improve air quality. Their advantages include fast refuelling, long range, and flexibility in different climatic conditions. In addition, financial support from the European Union makes it economically advantageous for manufacturers and public transport operators to invest in hydrogen buses.

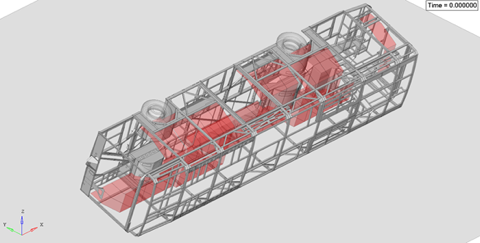

Endego is at the forefront of the industry not only through its expert knowledge of innovative propulsion solutions but also by providing customers with advanced durability calculations to meet the highest quality and safety standards. Endego’s bus design process includes precise structural analyses, taking into account a variety of operating conditions and potential extreme situations.

Advanced calculation technologies make it possible to precisely recalculate the steel structure of a bus, taking into account all aspects of safety and durability. At Endego, we not only focus on the standard mandatory standards for city buses, but also take care to meet the additional regulations required by our customers, such as those governing the bus’s rollover and roll-over behaviour. This diligence in strength calculations is a key element for the durability and reliability of the vehicles. Through rigorous testing, Endego ensures the long service life of the buses and, above all, the safety of the passengers.

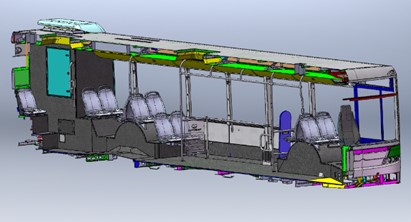

We design vehicles with a view to ensuring maximum comfort for travellers. Believing that travelling using urban public transport can and should be comfortable and enjoyable, Endego is committed to creating interiors that meet the expectations of even the most demanding users.

When designing bus interiors, our engineers emphasise the ergonomics of their layouts. They provide comfortable seating and spacious passageways. The use of modern materials, technology, and amenities makes bus travel a pleasant experience.

When designing buses for comfort, Endego also takes into account the diverse needs of passengers, including those with disabilities. Our vehicles are equipped with accessibility solutions such as ramps or special seats for people with reduced mobility. All this makes the bus journey easier, more comfortable, and possible for all passengers.

One of the key aspects that sets Endego apart from the competition is also the use of state-of-the-art communication technology. The buses we design are equipped with passenger information systems that provide up-to-date information on timetables, delays, and other relevant aspects of the journey. This allows passengers to plan their journeys with greater accuracy and avoids unnecessary waiting.

New technologies in bus design open the door to creativity and innovation in form and design. The use of materials such as aluminium or laminates allows bus manufacturers to frequently upgrade silhouettes. This flexibility in design allows the creation of innovative shapes, giving vehicles a unique character.

Bus designers can now turn to futuristic forms that not only attract attention but also improve aerodynamics or energy efficiency. Modern bonding technologies, which are replacing traditional welding methods, make it possible to achieve more complex shapes and open up completely new possibilities for designers.

Endego can boast impressive design projects, such as exterior and interior styling for leading Polish manufacturers or the design of a bus silhouette for the Swedish market. Adapting different lengths of buses, creating articulated designs or modular buses are just some of the challenges that our company tackles with passion and commitment.

Looking to the future, we see developing technology that will enable futuristic shapes to be given to green energy-powered buses. Our company’s activities are in line with the European hydrogen strategy, a further step towards a climate-neutral Europe.

The comprehensive approach to bus design used by our company includes not only technical aspects but also attention to the travel experience for every passenger. In this way, Endego is not only defining new standards of efficiency but is also part of the direction in which public transport is becoming as comfortable as it is environmentally friendly. Write to us and find out how we can support your project.

Rolling stock modernisation is becoming an increasingly attractive alternative to purchasing new vehicles, especially with rising costs, budget constraints and the need to operate in line with sustainable development principles. When does modernisation make sense and how can it be carried out effectively?

Read moreToday, bumpers are much more than just components that protect against the effects of collisions. They are advanced components that combine safety, aerodynamics, aesthetics and integration with electronic systems. How are they designed and why are they so important in modern vehicles?

Read moreModern trains are not just means of transport, but also embody innovation and safety. The design of the front end and car body combines aesthetics with advanced engineering and European standards. How does the appearance of a train affect its aerodynamics, energy consumption, safety and brand image? Here’s what’s behind the modern design of rolling stock.

Read more