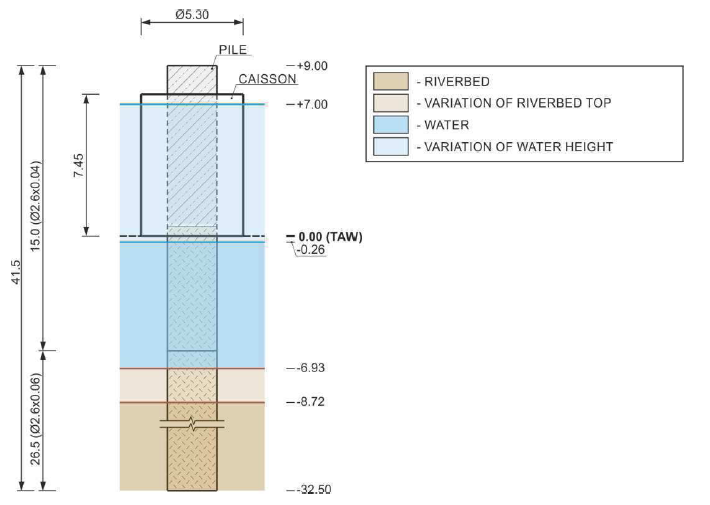

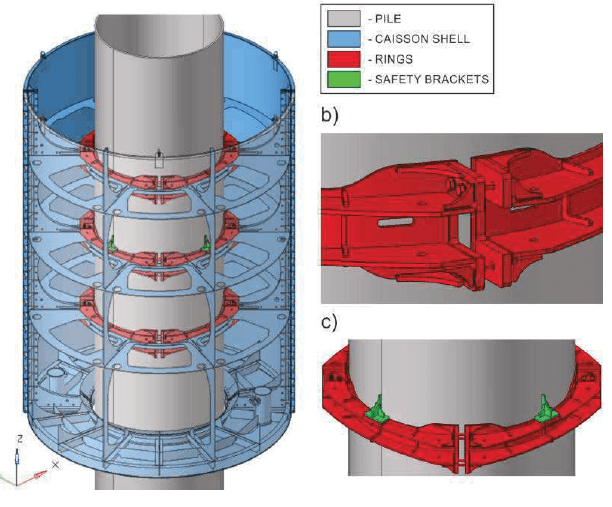

Design and strength calculations to verify the construction of a tank (caisson). The caisson is designed for below-water welding work on piles embedded in the bed of the Skalda River for mooring watercraft.

Design and strength calculations to verify the construction of a tank (caisson). The caisson is designed for below-water welding work on piles embedded in the bed of the Skalda River for mooring watercraft. The project’s main objective was to develop a caisson design that is fixed to the piles while minimising interference with their structure.

Structural design of the caisson with strength calculations. The design was made in Solidworks, the strength calculations of the caisson were carried out in the OptiStruct Analysis environment of the HyperWorks package, using the quasi-static non-linear calculation algorithm.

A successfully completed structure that meets the client’s requirements.

Rolling stock modernisation is becoming an increasingly attractive alternative to purchasing new vehicles, especially with rising costs, budget constraints and the need to operate in line with sustainable development principles. When does modernisation make sense and how can it be carried out effectively?

Read moreToday, bumpers are much more than just components that protect against the effects of collisions. They are advanced components that combine safety, aerodynamics, aesthetics and integration with electronic systems. How are they designed and why are they so important in modern vehicles?

Read moreModern trains are not just means of transport, but also embody innovation and safety. The design of the front end and car body combines aesthetics with advanced engineering and European standards. How does the appearance of a train affect its aerodynamics, energy consumption, safety and brand image? Here’s what’s behind the modern design of rolling stock.

Read more