The automotive industry is a highly demanding market. It shows especially in areas of quality and project risk. Every company faces difficulties achieving high standards, avoiding unnecessary risk and complicated issues before their product gets to an end user. Various standards and guidelines help address these issues. ASPICE is the best-known example of such.

ASPICE (or Automotive SPICE) is the main framework and standard to determine a proper product development structure. It was developed near the end of 1990 by German companies such as BWM, BOSCH, Continental, Daimler, and Volkswagen. In the beginning, it addressed mainly fields related to software and system engineering. However, the new revisions apply also to mechanical, hardware, and overall engineering areas. Nowadays, ASPICE has much broader usage in process improvement in the automotive sector than it used to. It serves as a process assessment tool for OEMs, giving an insight into the quality of product development of a supplier. Today, we will skip the part related to the assessment process and focus mainly on how ASPICE could be a guide to improve the everyday work of a company.

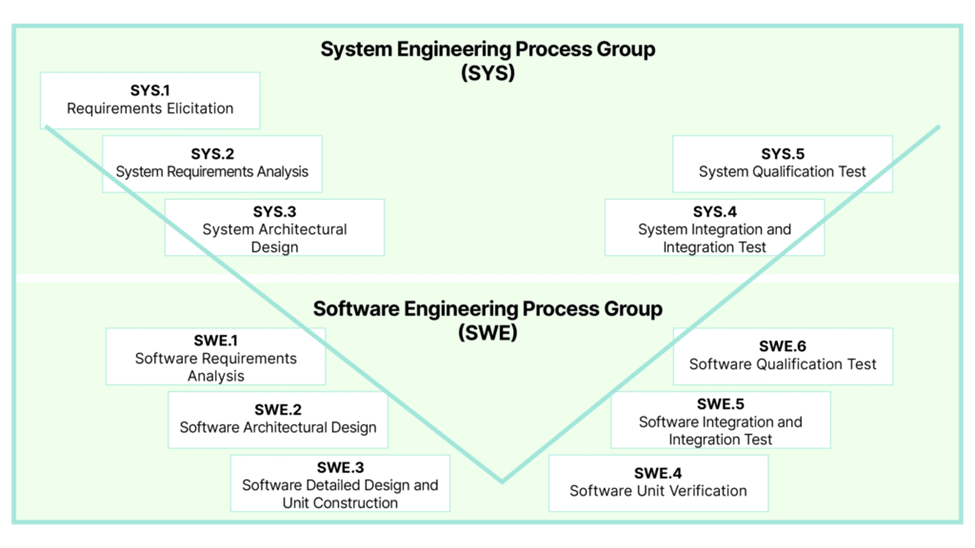

Take a look at the overview graph with the V-model used in ASPICE:

You will see that the above process steps are V-shaped. It is from where the V-model took its name. The main areas described here are System Engineering and Software Engineering. However, new revisions of the ASPICE also address other parts of the process.

In general, product development starts from the top left corner step SYS1 and goes down through other steps. You can separate three main sections of the V-letter:

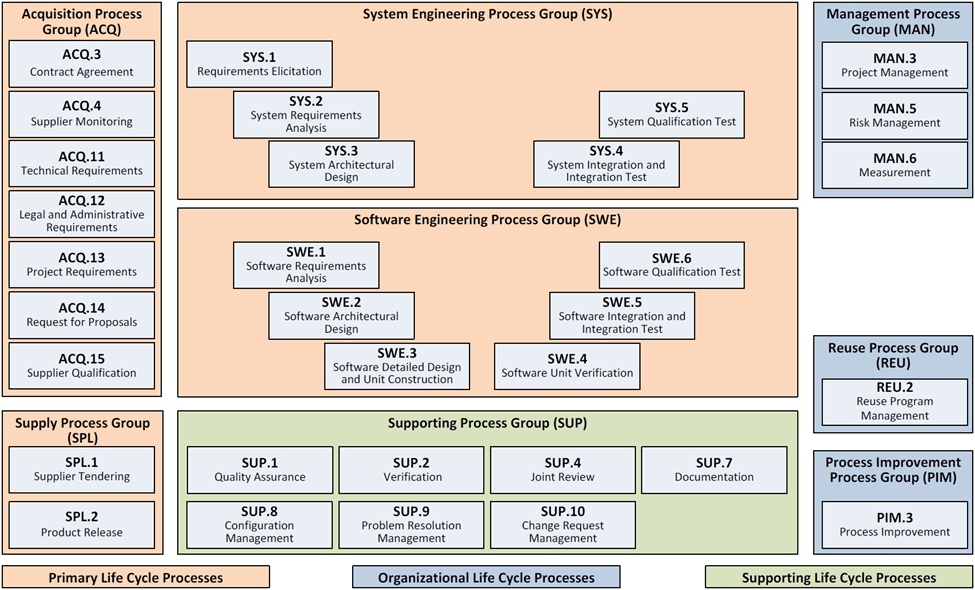

It’s a general V-Model overview. However, ASPICE has more steps worth describing:

The above overview comes from the ASPICE v3.1 revision of the guideline document. You can see that ASPICE addresses various processes during the product life cycle. It aims to support product development and provide clues how to report, verify, and improve the information flow.

There are several benefits to introducing an ASPICE way into your product development:

Although ASPICE is a highly functional framework in the automotive industry, it is not challenges-free. Applying this framework connects with challenges, especially at the beginning, such as:

If you would like to find out more about ASPICE, I suggest looking for free guideline documents and a pocket guide that can help you understand each process step. Next time, I will try to explain how to use ASPICE to assess processes during the product life cycle.

Car manufacturing has undergone constant change over the years to adapt to a changing world. The process of e volvement in the automotive sector is not stopping – there are constantly new challenges and circumstances that car manufacturers are trying to meet. The dynamic nature of this segment of the global market is perfectly illustrated by the changes that are taking place in the area of materials used in cars. One of the main trends we can observe is the desire to create vehicles based on lightweight yet durable components. There is also a strong emphasis on recyclates and renewable materials in the choice of materials for cars.

Read moreTrends in energy management, the development of electric and hybrid vehicles, as well as innovations in fleet management and labor optimization are influencing manufacturers and operators of off-highway machinery. The application of modern solutions from these areas can significantly contribute to improving the energy efficiency of the entire off-highway sector.

Read moreDue to its practical as well as aesthetic functions, the ‘grill’ is one of the vehicle components that receive special attention in terms of design. What does this process look like from the initial concept stage through to series production?

Read more