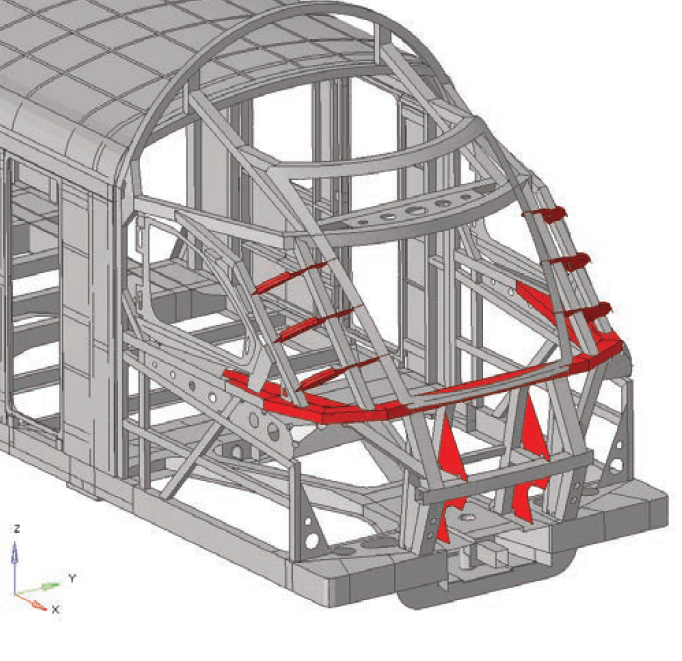

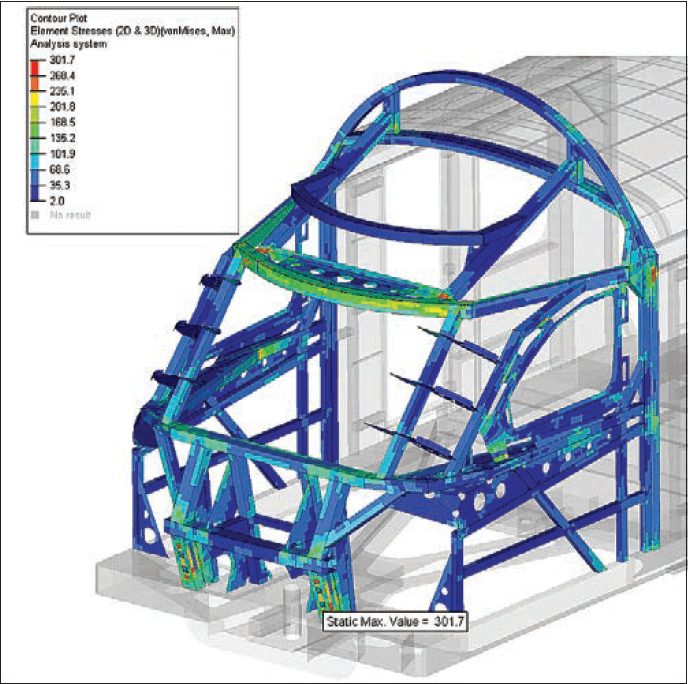

Modernization of the structure of the front of the ED72 electric multiple units, taking into account static, fatigue, and crashworthiness requirements.

Modernization of the structure of the front of the ED72 electric multiple units, taking into account static, fatigue, and crashworthiness requirements.

The upgraded ED72 unit front structure met all the requirements in terms of functionality, static, impact, and fatigue strength.

Trends in energy management, the development of electric and hybrid vehicles, as well as innovations in fleet management and labor optimization are influencing manufacturers and operators of off-highway machinery. The application of modern solutions from these areas can significantly contribute to improving the energy efficiency of the entire off-highway sector.

Read moreDue to its practical as well as aesthetic functions, the ‘grill’ is one of the vehicle components that receive special attention in terms of design. What does this process look like from the initial concept stage through to series production?

Read moreIntroducing a flawless product has always been a goal of all OEMs in the Automotive Industry. Unfortunately, product development has become more complex over the years. A growing number of suppliers involved creates a situation requiring checking if teams provide the correct elements of your final product. The purpose of ASPICE is to assess process steps and give tools to put a rating of your partners’ process development.

Read more